|

|

|

|

Kuen-Shyang Hwang

黃 坤祥

Adjunct Professor

Ph.D,

Rensselaer Polytechnic Institute

Phone: +886-2-2363-3126

Fax: +886-2-2363-4562

E-mail: kshwang@ccms.ntu.edu.tw

|

Background:

|

1971-1975 B.S. in Mechanical Engineering, National

Taiwan University.

1977-1978 M.S. in Materials Science and Engineering, Rensselaer

Polytechnic Institute.

1979-1980 Emporium Specialties.

1981-1984 Ph. D in Materials Science and Engineering,

Rensselaer Polytechnic Institute.

1984-1988 Packaging Manager, General Instrument, Long Island,

N.Y.

1988- Dept. of

Materials Science and Engineering, National Taiwan University.

|

Services:

Adjunct

Professor, National Taiwan University

President, P/M Assoc.

R.O.C. (Taiwan) (2003-2007)

Research Interest:

Traditional

Powder Metallurgy

Metal Injection Molding

(MIM)

Sintering Theory

Journal Publications Since 2005

- K.

S. Hwang and G-J Shu, “Solvent Debinding Behavior of PIM Components Prepared from

Powders with Different Particle Sizes”,

Metallurgical and Materials Transaction A, 2005, Vol. 36A, pp. 161-167.

- K.

S. Hwang, T. H. Yang, and S. C. Hu, “Diamond

Cutting Tools with a Ni3Al Matrix Processed by Reaction Pseudo-Hipping”, Metallurgical

and Materials Transaction A, 2005, Vol. 36A, No. 10, pp. 2801-2806.

- Guo-Jiun Shu and Kuen-Shyang Hwang,

“Effect of

Heating Rate and Phase Transformation on the on the Dimensional Control

of Ferrous PIM Compacts”, Materials Transactions,

JIM, 2005, Vol. 46, No. 2, pp. 298-302.

- K.

S. Hwang, “Effect of Alloy

Composition and Sintering Parameters on the Dimensional Stability of PIM

Compacts”, P/M

Technology, 2005, Vol. 23, No. 2, pp. 134-139.

- K.

S. Hwang and C. C. Hsieh, “Injection-Molded

Alumina Prepared with Mg-Containing Binders”, J. Am. Ceram.

Soc., 2005, Vol. 88, No. 9, pp. 2349-2353.

- G.

J. Shu, K. S. Hwang, Y. T. Pan, “Improvements in

Sintered Density and Dimensional Stability of Powder Injection Molded

316L Compacts Through Adjusting Alloying Compositions”, Acta Materialia, 2006.

Vol. 54, No. 5, pp. 1335-1342.

- M.

W Wu, K. S. Hwang, H. S. Huang, and K. S. Narasimhan,

“Improvements in

Microstructure Homogenization and Mechanical Properties of Diffusion

Alloyed Steel Compact by the Addition of Cr-containing Powders”, Metallurgical

and Materials Transaction A, 2006, Vol. 37A, pp. 2559-2568.

- M.

W. Wu and K. S. Hwang, “Improved

Homogenization of Ni in Sintered steels Through the Use of Cr-Containing

Prealloyed Powders”, Metallurgical

and Materials Transaction A, 2006, Vol. 37A, pp. 3577-3585.

- M.

W. Wu and K. S. Hwang, “Identifications

of Crack Initiation Sites of Ni-Containing Steels and Methods for

Property Improvement”, Advances in

Powder Metallurgy and Particulate Materials, 2006, Part 5, pp. 58-71.

- B.Y.

Chen, K.S. Hwang and C. C. Wang, "Thermal Dissipation Performance

of Heat Sink /Vapor Chamber Prepared by Metal Injection Molding Process

", J. Materials Science and Engineering, (Chinese) 2006, Vol. 38,

No. 1, pp. 49-55.

- R.

M. German and K. S. Hwang,“The Status of

MIM, PIM, and Related PM Technology in the USA”, 2006,Powder

Metallurgy Technology, vol. 24, no. 5, pp. 384-387.

- K.

S. Hwang and Y. W. Hsueh, “Post-Sintering

Thermal Treatment of Nitrogen-Containing Pressed-and-sintered and PIM

Stainless Steels”, Powder

Metallurgy, 2007, Vol. 50. No. 2, pp. 165-171.

- K.

S. Hwang, M. W. Wu, F. C. Yen, and C. C. Sun, “Improvement in

Microstructure Homogeneity of Sintered Compacts Through Powder Treatment

and Alloy Designs“, Materials

Science Forum, 2007, Vol. 534-536, pp. 537-540.

- Yang-Liang

Fan and Kuen-Shyang Hwang, “Properties of

Metal Injection Molded Products using Titanate-containing

Binders”, Materials

Transactions, JIM, 2007, Vol. 48, No. 3, pp. 544-549.

- M.

W. Wu, K. S. Hwang, and H. S. Huang, “In-Situ

Observations on the Fracture Mechanism of Diffusion Alloyed

Ni-Containing PM Steels and a Proposed Method for Tensile Strength

Improvement”, Metallurgical

and Materials Transaction A, 2007, Vol. 38A, pp. 1598-1607.

- K.

S. Hwang and M. W. Wu, “Sinter-Hardened

Ultrahigh-Strength PM Steels with Homogeneous Alloying and

Microstructures”, Advances in

Powder Metallurgy and Particulate Materials, 2007, Part 5, pp. 53-67.

- M.

W. Wu and K. S. Hwang, “The Mechanisms

of the Formation and Elimination of Weak Ni-rich Areas in PM Steels”, Advances in

Powder Metallurgy and Particulate Materials, 2007, Part 7, pp. 12-23.

- Y.

L. Fan and K. S. Hwang, “Causes of

Defects and Deformations in Powder Injection Molded Components during

Solvent Debinding”, Advances in

Powder Metallurgy and Particulate Materials, 2007, Part 4, pp. 38-48.

- Yang-Liang

Fan, Kuen-Shyang Hwang, and Shao-Chin Su, “Improvement of

the Dimensional Stability of Powder Injection Molded Compacts by Adding

Swelling Inhibitor into the Debinding Solvent”, Metallurgical

and Materials Transaction A, 2008, Vol. 39A, pp. 395-401.

- M.

W. Wu, K. S. Hwang, and K. H. Chuang, “Improved

Distribution of Nickel and Carbon in Sintered Steels through the

Addition of Chromium and Molybdenum”,

Powder Metallurgy, 2008, Vol. 51, No. 2, pp. 160- 165.

- K.

S. Hwang, M. W. Wu, and C. C. Tsai, “High

Strength Sinter-Hardening Powder Metallurgy Alloys”, Advanced

Materials Research, eds. Y-J Lin and W-C J. Wei, 2008, Vol. 51, Eng.

Mat. III, pp. 3-9.

- Y.-L.

Fan and K. S. Hwang, “Binder

Distribution in Powder Injection Molded Compacts during Solvent and

Thermal Debinding”, Chinese J.

Mechanical Engineering, 2008.

- Yang-Liang

Fan, Kuen-Shyang Hwang, Shiau-Han

Wu, and Yau-Ching Liau,

“Minimum Amount

of Binder Removal Required during Solvent Debinding

of Powder Injection Molded Compacts”,

Metallurgical and Materials Transaction A, 2009, Vol. 40A, pp. 768-779.

- Yueh-Ju Lin and Kuen-Shyang Hwang, “Effects

of Particle Size and Particle Size Distribution on Heat Dissipation of

Heat Pipes with Sintered Porous Wicks”,

Metallurgical and Materials Transaction A, 2009, Vol. 40A, pp.

2071-2078.

- K.

S. Hwang, Y. C. Lu, G. J. Shu, and B. Y. Chen,

“Enhanced

Densification of Carbonyl Iron Powder Compacts by the Retardation of

Exaggerated Grain Growth through the Use of High Heating Rates”, Metallurgical

and Materials Transaction A, 2009, Vol. 40A, pp. 3217-3225.

- L.

H. Cheng, K. S. Hwang and Y. L. Fan, “ Molding Properties and

Causes of Deterioration of Recycled Powder Injection Molding Feedstock”, Metallurgical

and Materials Transaction A, 2009, Vol. 40A, pp. 3210-3216.

- Y.

J. Lin and K. S. Hwang, “Effects of

Powder Shape and Processing Parameters on Heat Dissipation of Heat Pipes

with Sintered Porous Wicks”,

Materials Transactions, JIM, 2009, Vol. 50, No. 10, pp.2427-2434.

- K.

S. Hwang and C. H. Yang, “Diamond Cutting

Tools with a Ni3Al+10Cu Matrix”,

Int. J. Powder Metallurgy, Vol. 45, No. 6, 2009, pp. 37-43.

- Li-Hui Cheng and Kuen-Shyang

Hwang, “High-Strength

Powder Injection Molded 316L Stainless Steel”, Int. J.

Powder Metallurgy, Vol. 46, No. 2, 2010, pp. 29-37.

- Bor-Yuan Chen and Kuen-Shyang Hwang, “Comparative

Study of Carbon Black and Graphite Powder as the Carbon Source for PM

Compacts”, Powder

Metallurgy, 2010, Vol. 53, No. 1, pp. 51-56.

- K.

H. Chuang and K. S. Hwang, “Free-machining

PIM 316L stainless steels”, Powder

Metallurgy, 2010, Vol. 53, No. 1, pp. 57-61.

- M.

W. Wu and K. S. Hwang, “Formation

Mechanism of Weak Ferrite Areas in Ni-containing Powder Metal Steels and

Methods of Strengthening Them”,

Materials Science and Engineering A, 2010, Vol. 527, pp. 5421-5429.

- Yueh-Ju Lin and Kuen-Shyang Hwang, “Swelling

of Copper Powders during Sintering of Heat Pipes in Hydrogen-Containing

Atmospheres”, Materials

Transactions, JIM, 2010, Vol. 51, No. 12, pp. 2251-2258.

- Che-Wei Chang,

Po-Han Chen, and Kuen-Shyang Hwang, “Enhanced

Mechanical Properties of Injection Molded 17-4PH Stainless Steel through

Reduction of Silica Particles by Graphite Additions” Materials

Transactions, JIM, 2010, Vol. 51, No. 12, pp. 2243-2250.

- B.

Y. Chen, K. S. Hwang, and K. L. Ng, “Effect

of Cooling Process on the α

Phase Formation and Mechanical Properties of Sintered Ti-Fe Alloys”, Materials

Science and Engineering A, 2011, Vol. 528, pp. 4556-4563.

- Fu-Cheng

Yen and Kuen-Shyang Hwang, “Shape Memory

Characteristics and Mechanical Properties of High-Density Powder Metal TiNi with Post-sintering Heat Treatment”, Materials

Science and Engineering A, 2011, Vol. A528, pp. 5296-5305.

- K.

H. Chuang and K. S. Hwang, “Preservation

of Geometrical Integrity of Supersolidus-Liquid-Phase-Sintered

SKD11 Tool Steels Prepared with Powder Injection Molding”, Metallurgical

and Materials Transaction A, 2011, Vol. 42A, in press.

- Fu-Cheng

Yen, Kuen-Shyang Hwang, Shyi-Kaan

Wu, and Shiau-Han Wu, “TiNi Shape Memory

Alloys with High Sintered Densities and Well-Defined Martensitic

Transformation Behavior”, Metallurgical

and Materials Transaction A, 2011, accepted.

Text Book

黃坤祥著:”粉末冶金學”第二版二刷。 中華民國粉末冶金協會。2008年9月出版

Chapter 11, Common Defects found in Metal Injection Molding, Handbook of

Metal Injection Molding, ed. D.

F.

Heaney, Woodhead Publishing, Cambridge, 2011.

專利

- 黃坤祥、陸永忠,”

燒結硬化粉末及其燒結體”,中華民國專利I294318,2008,3月。

- K.

S. Hwang and Y. C. Lu, “Sinter-Hardening

Powder and Their Sintered Compacts”,

德國專利102006027851,

2007,7月。

黃坤祥、陸永忠,” 一種燒結體及其製造方法”,中華民國專利 I

246947號,2006,1月。

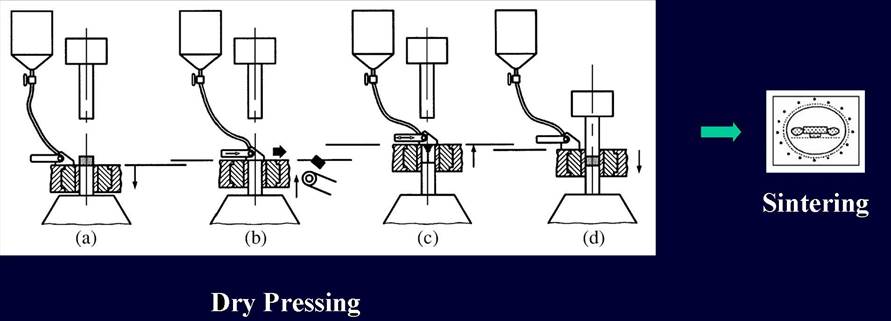

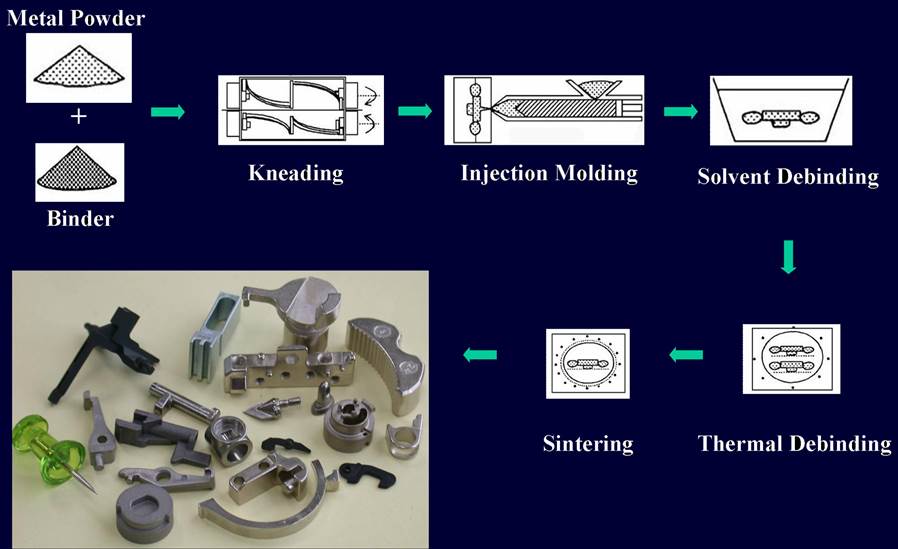

About Powder Metallurgy:

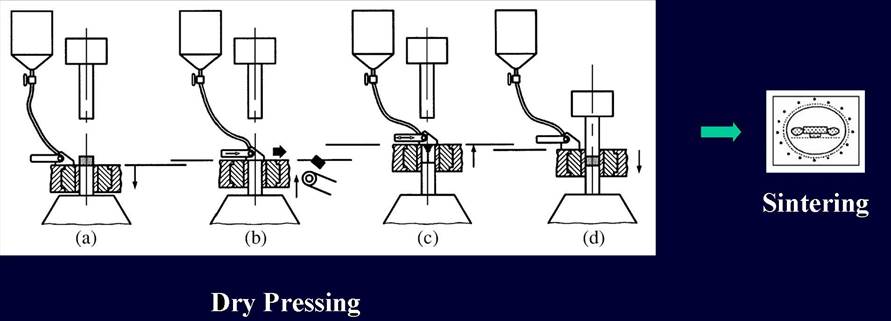

(a) Traditional Powder Metallurgy

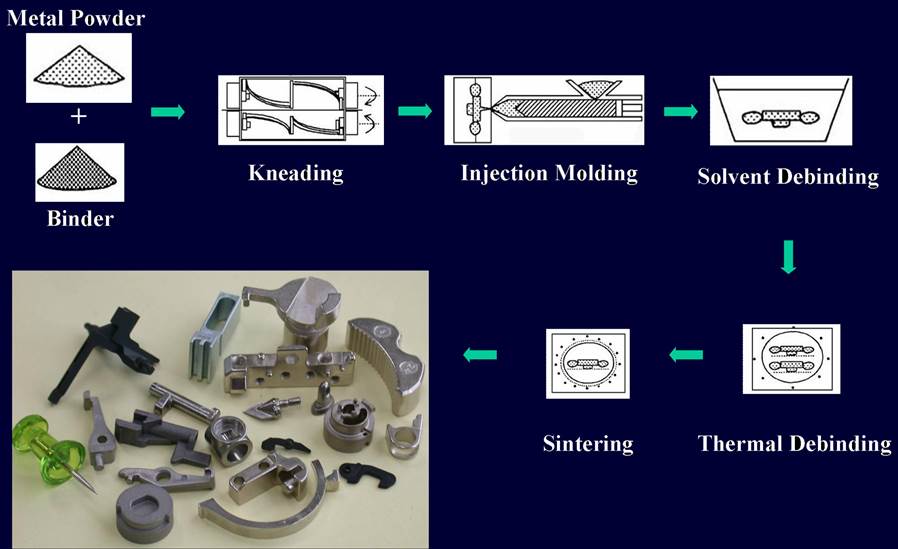

(b) Metal Injection Molding (MIM)

Advantages of Powder Metallurgy:

1.High Shape Complexity

2.Little Machining

3.Smooth Surface

4.High Volume Production

5.High Mechanical Properties

2011

Powder Metallurgy Laboratory.

Wedsite administrator: Chen Hsu

|