|

I.

Surface

Modification of Steels History of the usage of

stainless steel has existed for so many years. In our lab, hot-dip galvannealed

sheet steel is mainly focused. Hot-dip galcannealed sheet steel is a widely utilized source for

automotive body panels and parts due to its excellent corrosion resistance

properties. Although the alloying

process and lubrication during working improves the formability of the sheet

steel, for large and more complex parts, a more developed lubricant film

coating is required during molding and working process. In addition, the

Fe-Al interfacial layer is also considered to have some effects. |

|

Surface Coating on Advanced High Strength Steels

|

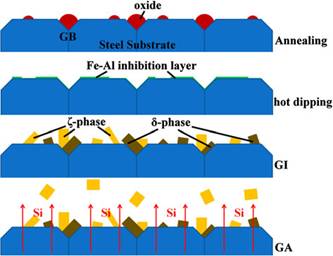

When the pre-coating

annealing process was conducted at an extremely low dew point, the external selective

oxidation prevailed, resulting in various oxides on the steel surface.

However, the oxides did not fully cover the steel surface under the reduction

atmosphere. Therefore, the molten Zn(Al) reacted

locally with the steel surface to form Fe-Al inhibition alloys. Moreover, the

Al in the molten Zn(Al) bath effectively removed the

oxides by aluminothermic reduction. This Fe-Al

inhibition alloy was then gradually transformed to Al-bearing Fe-Zn phases.

During the following GA process, the diffusion of Si from the steel substrate

to the coating apparently suppressed the forming of the ζ

phase, in which the Si is almost indissoluble. As a result, the Fe-Zn alloy

formation was largely retarded; specifically, a discontinuous Fe-Zn IMCs

layer was formed after 25 seconds of galvannealing

at 773 K (500 ℃). |

|

|

II.

Surface

Modification of Titanium-based Alloys Due to the truth of titanium

and its alloys have excellent biocompatibility with bone tissues,

they are well-selected as implant materials. In this case, a calcium- and

phosphorus-containing film on titanium had been proved to further enhance its

bioactivity after being implanted in human body. We recently focused on the microarc oxidation process to have the surface of titanium be modified. Besides, the SBF immersion process were found to be able to increase the contents of calcium and phosphorus in the anodic film. |

|

|

III.

Surface

Modification of Magnesium-based Alloys Magnesium alloys have become a

group of the most widely used materials for their outstanding mechanical

properties. However, the poor corrosion resistance is a critical weakness of

most magnesium alloys. In improving their resistance to corrosion, surface

modification is an indispensable process. Among various modification

treatments, conversion coating

and anodic oxidation are the most commonly used methods. In the conversion coating for the

magnesium alloys, we have worked for several years on various systems,

including chromate, phosphate-permanganate, and rare-earth metals. Beside the

improvement, our researches especially focus on the microstructure and the

mechanism, which are still less disscussed now. |

|

Conversion Coating on Mg Alloys

|

The formation

mechanism of conversion coating on magnesium alloys is a topic of both

thermodynamics and kinetics.

Through various characterizations, a further understanding of the

relations among microstructure, compositions, and electrochemical properties

may be acquired, which is of great help in developing conversion coating

systems providing sufficient corrosion resistance and mechanical properties. |

|

Permanganate Conversion Coating on AM30 Magnesium

Alloys

|

The hexavalent chromate conversion coating (CCC) developed by

the Dow chemical company had been widely adopt to improve the corrosion

resistance of magnesium alloys. However, hexavalent

chromium is harmful to human health. Consequently, replacing traditional

chromate conversion coating with a new developed conversion process becomes

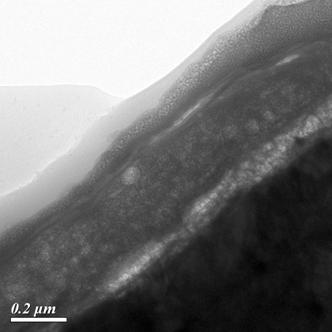

increasingly essential. The TEM

image showed that the thickness of permanganate coating is approximately 200

nm, and the coating is mainly composed of manganese dioxide with an amorphous

structure. In short, the permanganate conversion coating showed better

adhesion and less severe crack by virtue of increasing the chemical

reactivity and

lowering the immersion time, expecting to replace hexavalent chromate conversion coating and reduce the

cost of production. |

|

Cerium Conversion Coating on AZ91 Magnesium Alloys

|

Cerium

conversion coatings were made on AZ91 magnesium plates in cerium nitrate

aqueous solution with H2O2. H2O2

addition increases the reaction rate; however, the blisters on the conversion

coating cause poor adhesion and deteriorate the corrosion resistance of the

cerium conversion coating. An alternative approach by the addition of sodium metavanadate (NaVO3) was used to solve the

formation of blisters. Microstructure observation shows that complex

precipitates are formed on the coating and the amount of blister is

significantly reduced. The results suggest that the presence of VO3-

plays an important role in inhibiting the formation of blisters. (Figure.(a)-(b)

Surface morphology of the cerium conversion coating with/without NaVO3,

immersion time 20s; (a) many blisters remains on the cerium conversion

coating without NaVO3 and (b) some precipitates forms on the

coating whereas the blisters are eliminated effectively.) |

|

IV. Electrochemical deposition

|

Electrochemical

deposition is a kind of chemical reaction which has been investigated for a

long run, and the process applies to lots of fields and industries, such as the

automobile industry, cellular phone industry and anti-corrosion field. In

electrochemical process, the main idea is applying an electric field, driving

the cations in electrolyte to be reduced on the

cathode. All the electrochemical reactions happen on the surface of

electrode, hence also regarding as a type of surface science. By means of

method, we can get the material we want or modify the surface of the

electrode. |

|

CIS/CIGS solar cell

|

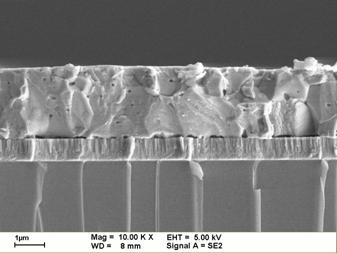

Cu(InGa)Se2-based

solar cells have often been touted as being among the most promising of solar

cell technologies for cost-effective power generation. This is partly due to

the advantages of thin films for low-cost, high-rate semiconductor deposition

over large areas using layers only a few microns thick and for fabrication of

monolithically interconnected modules. Perhaps more importantly, very high

efficiencies have been demonstrated with Cu(InGa)Se2 at both the cell and the module

levels. Currently, the highest solar cell efficiency is 19.2% with 0.5 cm2

total area fabricated by the National Renewable Energy Laboratory (NREL). The

picture above show the plan view and cross-sectional images of Cu(InGa)Se2-based

solar cells which fabricated by the National Renewable Energy Laboratory

(NREL). A compact grain structure is observed in cross-section, and faceted

grains are visible in plan view. |

|

V.

Sol-Gel

process

|

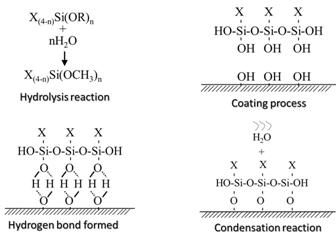

Sol-gel process Is a method

for producing thin films or solid materials. The mechanism of sol-gel process

is the combinative chemical reaction of hydrolysis and condensation. The

precursor such as alkylsiloxane would be hydrolyzed

to the silanol by adding deionized

water in proper pH value. Then the silanol was

self-condensation by removing water. The products formed to the silica

finally. The surface morphology or surface chemical activity could be

modified by sol-gel process. It is widely used in powder metallurgy,

ferroelectrics, superconducting material, ceramic material,

thin film, etc. |

|

Sol-gel coating on the HDG steels

|

Zinc

coating provided the barrier protection and the sacrificial protection over

the steel substrate. To further protect the Zn-coated steel against corrosion

during its transportation and storage, surface modification is generally

adopted. The sol gel coating process was involved the hydrolysis reaction and

the condensation reaction of the precursor. This study is aim to produce a

functional and environmental friendly coating with an excellent corrosion

protection performance on the zinc substrate using a sol-gel process |

|

| Faculty | Research | Teaching | Members | Downloads | Links | Home |

2007

Surface Modification Laboratory. All Right Reserved.

Website administrator: Daniel MT Chen

Website updated by Z.K. Chen